Volume 1. Are you on an island of automation?

Hi! This is a bi-weekly newsletter of everything interesting in Supply Chain from Shenzhen to San Francisco. Every edition we'll be meeting with someone enabling your Supply Chain to run harder, better, faster, stronger. You'll also hear about recent, compelling partnerships between corporates and startups, and the latest funding rounds from interesting startups. Subscribe below to work it, make it, do it.

Connecting islands of automation with Dexterity Robotics 🏝

We talked to Mike Hyslop, the VP of Business Development at Dexterity Robotics, a Pick-and-Place warehouse automation startup that just came out of stealth. Read on to understand how they differentiate themselves from competitors, how long a deployment takes, and the three questions you should consider before thinking about robotics!

FORGE: Congratulations on coming out of stealth! What does it really mean, to come out of stealth? And why make the decision now?

Mike: Well, candidly, I think we stayed in stealth as long as we did just because we were quite busy. There is tremendous demand for robotics, especially AI-powered, machine learning-powered robotics.

That's a good problem to have! Has something happened in robotics for them to be in such demand now?

Robotics has been around for 40 or 50 years, they’ve been the backbone of manufacturing. What's changed is that robotics is making a transition from manufacturing to supply chain. The problem with supply chain, unlike manufacturing, is that everything is highly unstructured. You have a lot of portable automation and ever-changing business strategies in supply chain. Then there are those islands of automation.

Islands of automation?

If you go to a warehouse or a distribution center you'll see the most sophisticated setups - a big retailer might have an Automated Storage/Retrieval System, or you might see some AMRs or AGVs buzzing around. One might go right between your legs! The AGVs are hauling boxes around and you might have a sophisticated packaging machine at the end.

Each one of these items exists as an island of automation. Everything in the front-end and back-end of it is highly manual and there is a cluster of labor there, why? There’s some kind of dexterity required- picking, placing, retrieving, shelving. Dexterity plans to connect the islands of automation.

So this is where your demand is coming from?

It's very easy for humans to pick shelves, retrieve, and organize things, but it's very difficult to automate for robotics. As a result, this has historically been a very labor-intensive part of the process within a supply chain. At Dexterity, our full-stack solution can provide the type of dexterity that's required to connect those islands of automation.

At Dexterity, our full-stack solution can provide the type of dexterity that's required to connect those islands of automation.

What would you like our clients to know about the Dexterity value proposition?

There's a lot of robotics noise out there. Our company's vision is to not just give you "robotics in a cage", we want to make robotics super smart. We want to transform our client's warehouses by seamlessly connecting them with robotics. We provide a team of robots that operate well with humans, and our solution is very portable and flexible. You can add robots on-demand, and we can scale with you during peak seasons.

And how does Dexterity differentiate itself from competitors? As you said, there's a lot of noise out there.

If you think of a triangle, in the bottom left corner, you have some companies that are very good at hardware - they provide a robot, computer vision, and a user interface. In the other corner of the triangle, you have the software provided by the AI/ML guys. But there's still something missing, and that's a sense of touch - contextual awareness for robotics. It’s that sense-of-touch that allows a robot to learn on-the-job and get better over time. That's the third point of the triangle, the missing delta. Instead of being focused on one point in that triangle, we deliver all three points. We are a full-stack solution.

But there's still something missing, and that's a sense of touch - contextual awareness for robotics

We also have a different way of looking at the marketplace. We're trying to have robots operate as a team, and also network them closely to humans, so we can seamlessly coordinate the inbound, the pick and pack, and the outbound. We take a more strategic view of the warehouse.

Learn how long a deployment with Dexterity takes, and the three questions to ask before deploying robotics here

Corporates ❤ Startups

In this segment, we dive into recent partnerships and developments in the Supply Chain ecosystem.

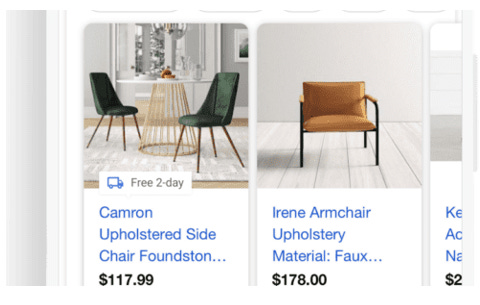

Ware2Go (US), an on-demand warehouse and fulfillment network (and a UPS spin-out!), integrated with Google Shopping to display free & fast delivery promises within merchant's Google ads.

Why does it matter? The Amazon Effect is real. Consumers expect convenience and timely deliveries, and the initial results from a beta proved this. Merchants who participated in the Ware2Go beta were able to offer free delivery to customers and saw a 7% increase in conversions, a 10% increase in conversions per dollar, and a 9% increase in overall conversion rate. I want my instant gratification, instant!

How does it work? Ware2Go operates a network of warehouses across the US that allows merchants to locate their goods closer to customers. Goods are fulfilled by UPS, so customers benefit from that trusted service too. This is a good example of a corporate venture taking advantage of their parent's unfair competitive advantages! I wonder how much influence Ware2Go's parent company had on this partnership?

Above: Merchants can dynamically display delivery promises to Google Shopping users.

Traxen (FR), a supply chain visibility startup, partnered with shipping giant COSCO to speed up their digitization efforts and provide transparency in ocean freight logistics.

Why does it matter? As the global supply chain becomes more and more competitive, improved tracking and smart data management is an increasingly important differentiation factor for all players in the shipping industry. The solution will provide COSCO with the ability to provide its customers with true door-to-door visibility. With supply chains still in flux as a result of COVID, we can only imagine how important this service must be to shippers

How does it work? Traxens "smart containers" allows partners to remotely track a range of data points including geo-location, shock detection, container door opening, temperature, and humidity fluctuations

Geek+ (CN), an AGV & AMR startup, already had a relationship with Decathlon, but the effects of COVID has led to a turbocharging of said relationship, with 170+ AMRs deployed to two sites in under three months.

Why does it matter? The shutting of physical stores, restricted work environments in fulfillment centers ... Decathlon's eCommerce supply chain had to deliver, quickly. In the past, Decathlon might have implemented a fixed automation solution with an ROI stretching over 5 years, but Geek+ enabled Decathlon to reap a 3x productivity increase, improve inventory capacity by 40%, and they estimate a ROI in under 3 years

How does it work? You probably already know how AMRs work. But you probably didn’t know that the training for the deployment of Geek+ was all done virtually through WeChat and Zoom! Additionally, Decathlon transferred robots from their retail stores to their eCommerce warehouses overnight. Talk about two adaptable and responsive companies!

Startups to keep an eye 💰n

In this section, we'll introduce recent funding rounds that we found particularly interesting.

What if you could shrink the footprint of your entire warehouse by 85%?

Attabotics (CA), a 3D fulfillment system built for eCommerce (you have to see it, to believe it), raised a $50M Series C with participation from Forerunner Ventures, Coatue Ventures, and others.

What is it? Attabotics' 3D storage structure enables AMRs to travel across the X, Y, and Z-axis. Workers then pick, place, and ship packages. This smaller footprint enables microfulfillment in dense urban locations for customers like Nordstrom.

Why we like it - Warehouse-on-Demand startups (see Ware2Go, also featured in this newsletter) are offering merchants the opportunity to be closer to their customers. If you already own real estate, Attabotics enables you to maximize your usage efficiency in ways that AMRs cannot do. Additionally, Attabotics offers a Fulfillment-as-a-Service business model, which means customers only pay for the service provided, not the hardware!

Feeling inspired? Check out:

Fabric - clients can set up a Fabric microfulfillment platform on their real estate or distribute products through Fabric's centers

Ocado Technologies - by 2020 Kroger plans to have nine microfulfillment centers powered by Ocado

What if you could digitize, measure, and transform your frontline workforce?

Parsable (US), a digital workflow platform, raised a $60M Series D with participation from Lightspeed Ventures, Saudi Aramco, and others.

What is it? Parsable enables organizations to create digital workflows that can connect with existing systems to trigger automated actions. This new data provides real-time visibility across the factory floor. Customers include Heineken, Shell, and Grupo Bimbo.

Why we like it - We sometimes forget about the people who don't sit behind a screen all day - Parsable brings SaaS productivity to the manufacturing floor. By connecting customer's IT & OT data to their now digitized processes, Parsable removes blinds spots in business operations and drives productivity, quality, and safety.

Feeling inspired? Check out:

What if you could orchestrate, track, and optimize your logistics operations?

FarEye (IN), a logistics management platform, raised a $38M Series D with participation from M12 (Microsoft), Honeywell Ventures, and others.

What is it? FarEye provides a logistics Control Tower that provides real-time visibility from first-mile seller pick-ups to last-mile delivery. This leads to a better customer experience and can lead to a reduction in costs across inventory and operations. Customers include Walmart, Domino's, and Godrej.

Why we like it - FarEye already works with over 150 brands, retailers, and 3PL providers. By coordinating the different players involved in fulfillment, every new customer adds to the natural network effect that strengthens the FarEye product. This creates an incentive for collaboration, which strengthens the optimization and value creation that FarEye provides!

Feeling inspired? Check out:

Wise Systems - automatically schedule, monitor and adjust delivery routes to improve last-mile operations

FourKites - obtain intermodal, real-time predictive visibility across your supply chain

If you're interested in learning more about these startups, please reach out at John.Low@bain.com.